CVD

Chemical Vapor Deposition is a chemical technology prepared from high-purity, high-performance solid materials.

ICP-CVD

ICP-CVD Inductively coupled plasma chemical vapor deposition is a chemical vapor deposition technique that uses ICP. It can provide some energy for the deposition reaction. Compared with the PECVD, ICP-CVD can deposit various films at a lower temperature without degrading the film quality. Using the ICP as a plasma source has the advantages of higher plasma concentration, lower energy loss, higher power and higher reaction rate. For SYSKEY's system can control the gas and real time record system data (pressure, substrate temperature), can perfectly produce high-quality thin films.

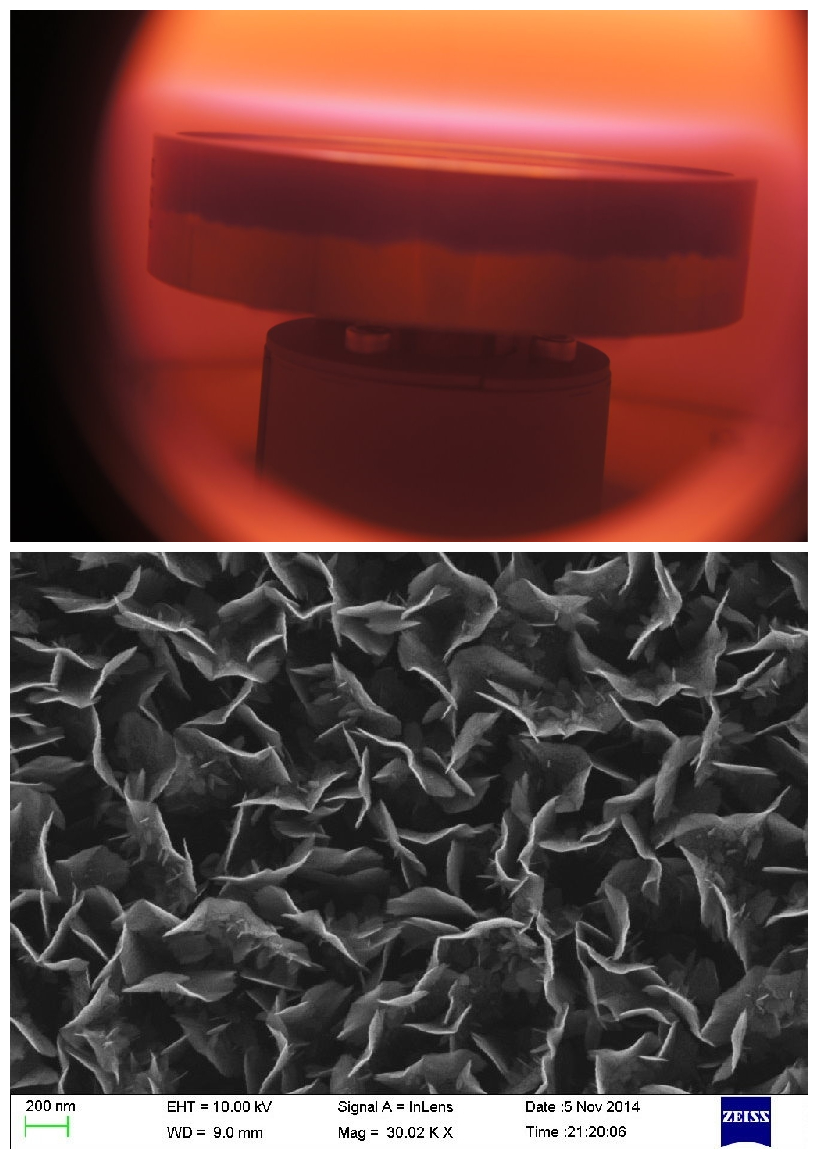

3 D Graphene

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|