Magnetron Sputter

Sputtering deposition is a PVD method in which a thin film is formed by sputtering a material from a target and then depositing it on a substrate.

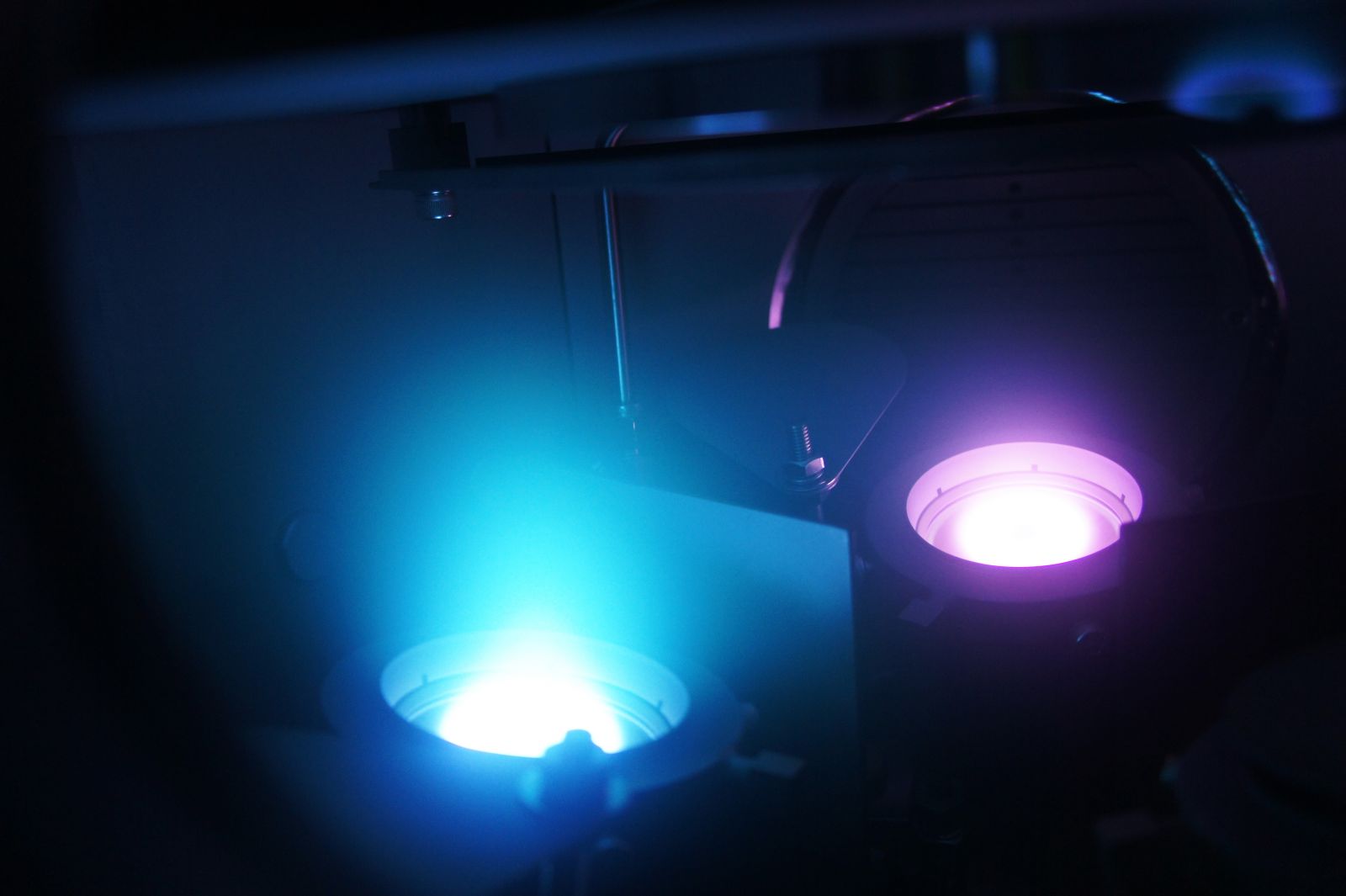

Co-Sputter

Co-sputtering is simultaneous coating from two or multiple sputtering targets. It is used for compound - alloy or composite material. The thin film is controlled by optimizing the power density of each gun (target). SYSKEY's magnetron co-sputtering system provides precise control of multiple magnetron sputtering process conditions to provide customers with the best quality composite film.

SYSKEY's sputter system has a single loading and cassette loading chamber, which can save the pumping time of the process.

%CB%87.jpg)

SYSKEY's sputter system can independently apply bias voltage on its stage part to clean and increasethe adhesion of materials.

Ion source can be used to clean the substrate and accelerate the sputtering speed of the coating material, and the ion beam helps deposit and compact the deposited films during the material deposition process.

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|