Plasma Etching

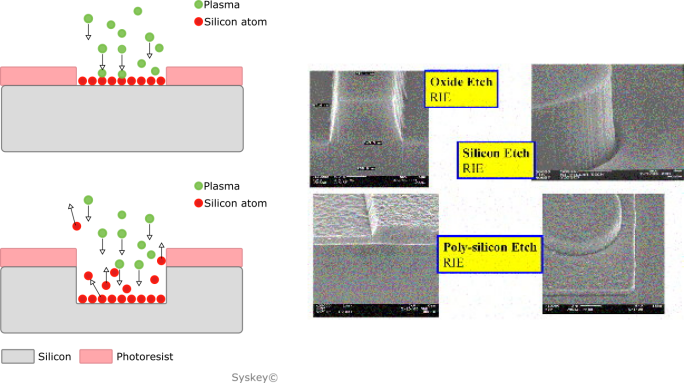

Dry etching is known as plasma dry etching is the process of removing materials from the surface of another material.

RIE

In reactive ion etching (RIE), its etching profile, etching rate, uniformity, and repeatability can be controlled very precisely. Isotropic etching profiles as well as anisotropic are possible.

Therefore, the RIE process is a chemical physical etching process, and is the most important process for constructing various films in semiconductor manufacturing. For SYSKEY's system can control the gas and plasma process, can perfectly produce high-quality thin films.

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|