Magnetron Sputter

Sputtering deposition is a PVD method in which a thin film is formed by sputtering a material from a target and then depositing it on a substrate.

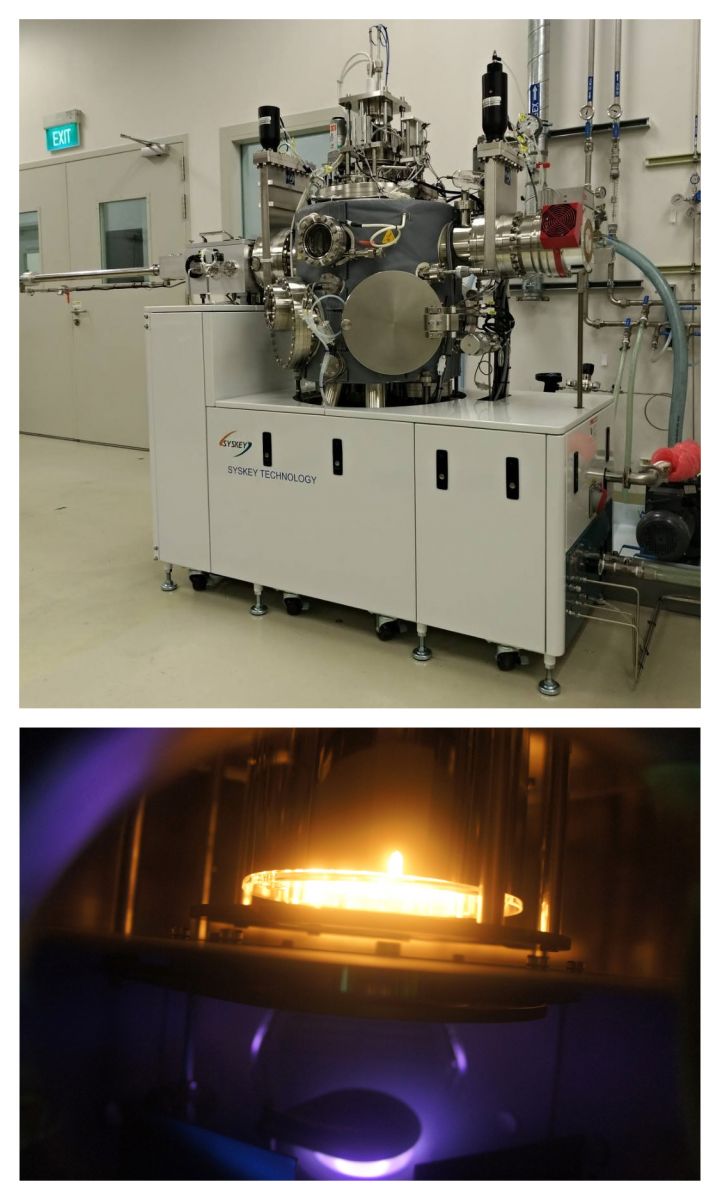

UHV Sputter

An UHV environment is characterized by pressures lower than 10-8 ~10-12 Torr and it is common in chemistry, physics, and engineering. For UHV environment, it is very important to scientific research, because experiments often require surfaces to be maintained in a contamination-free state for the duration of the process and use of low energy electron and ion-based experimental techniques without undue interference from gas phase scattering. In the Ultra-High Vacuum sputter system, SYSKEY can perfectly produce high-quality thin films.

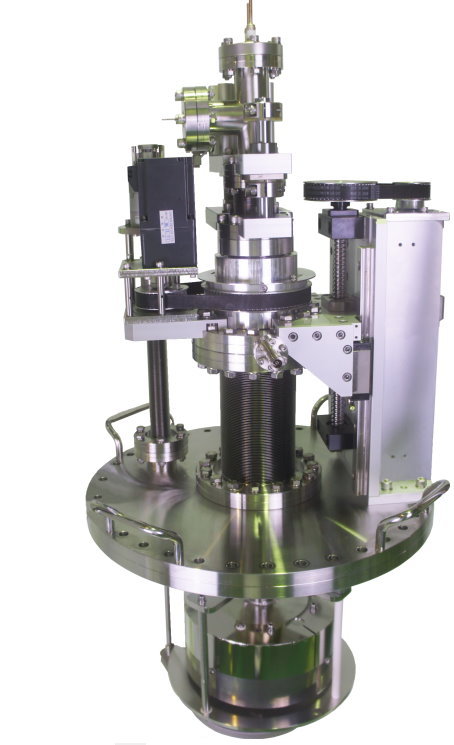

Design the substrate rotary coating mechanism for ultra-high vacuum and high temperature heating. Using ceramic Palin rotation, and do a water cooling cycle inside to protect the mechanism to makes sure the stability of long-term operation.

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|