Thermal ALD

The atomic layer deposition (ALD) system is a vapor-phase chemical deposition technique. It is one of the chemical vapor deposition methods.In most ALD reactions, two chemicals are used as precursors. These precursors react with the material surface in a continuous and self-limiting manner. By repeated exposure to the separated precursor, a thin film is slowly deposited. For thermal ALD requires relatively high temperatures (typically 150~350°C).

For SYSKEY's system can control the ALD process, the film thickness and uniformity is less than +/- 1%.

Thickness Uniformity (WIW):

A single 12-inch wafer is used to deposit Al2O3 and HfO2 films with a target thickness of 5nm. Use an ellipsometer (ellipsometer) to make a 27-point thickness measurement and bring in the standard deviation formula. Within ± 0.5nm and within 5% of uniformity.

| Al2O3 Uniformity=1.58% |

HfO2 Uniformity=1.27% |

.png) |

.png) |

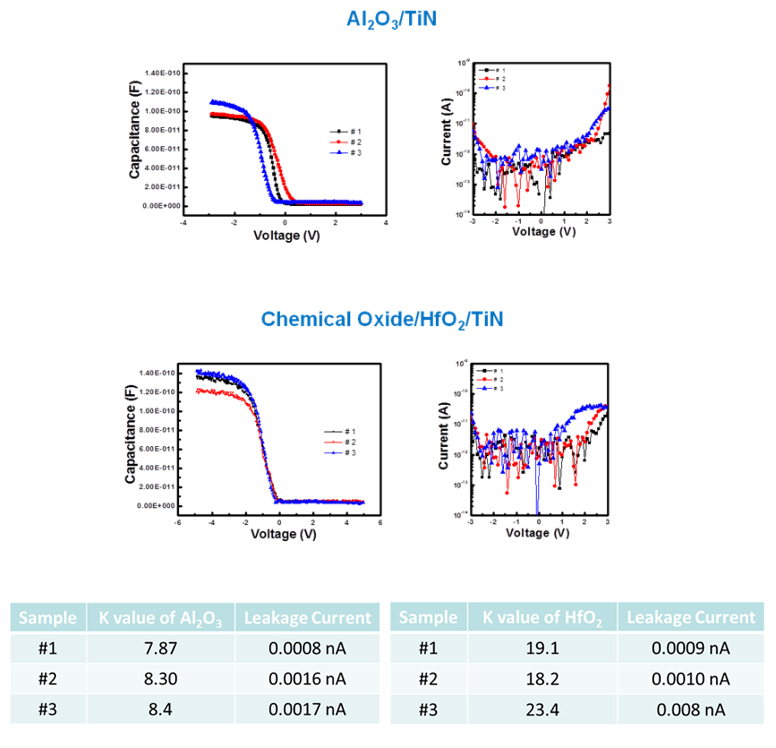

Dielectric constant and work function:

Prepare three silicon wafers and deposit Al2O3/ TiN and chemical oxide / HfO2 / TiN with a fixed thickness. Measure the CV diagrams of the three samples to calculate the dielectric constant and leakage current: The dielectric constant should be 7 ~ 9 (Al2O3) and 18 ~ 22 (HfO2), and the leakage current is less than 1nA (@ 1V).

| Applications | Chamber |

|

|

| Configurations and benefits | Options |

|

|